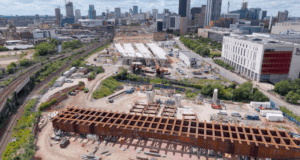

In collaboration with HW Martin (Traffic Management) Ltd, WJ Group have applied new road markings on the M6/M42 link road as part of long-term traffic management to support the construction of Phase One of the High-Speed rail network from London to Birmingham.

The project has several implications for the UK’s strategic road network, as new structures and road alterations are required to enable it to cross the road network.

They say, through their close partnership and knowledge of each other businesses, alongside shared aims of improving road worker safety and delivery efficiency, HW Martin (Traffic Management) Ltd worked with WJ to utilise two of their newest innovations on this scheme, the ThermoPrint and Autonomous PreMarker. These innovations both remove operatives from the potential dangers of working on the carriageway and into the safety of the vehicle.

Owing to the project’s long-term nature and considering future traffic management changes to the road layout to accommodate construction works, the WJ Autonomous PreMarker was deployed.

The WJ Autonomous PreMarker represents a significant advancement in road marking technology by dramatically enhancing safety and efficiency during the pre-marking process. Traditionally, and still primarily, this process is conducted manually, exposing operatives to significant safety risks and creating substantial inefficiencies. By integrating state-of-the-art GPS-based positioning, advanced camera equipment and sophisticated onboard computing, the Autonomous PreMarker automates this process, removing operatives from the carriageway and greatly increasing efficiency. It does this by recording the exact position of road markings at normal traffic speeds, and then accurately pre-marking before new markings are installed.

During this scheme, the equipment recorded all current longitudinal markings on this section of the network, so when they come to be changed and reinstated in years to come, the data will already be available to WJ, helping to improve efficiency and ensure they are replaced precisely where they were.

The second innovation utilised on this scheme was the ThermoPrint, which installed 10 sets of M6 & M42 markings and arrows, delivering multiple benefits for safety, efficiency and performance.

ThermoPrint is an automated road marking application machine that effectively removes the potentially hazardous, manual process of laying thermoplastic road markings by hand. This innovative technology shifts operatives from the carriageway to the safety of a vehicle cab, reducing the risks associated with working close to live traffic.

Productivity is also enhanced by enabling quicker application of road markings without the need to set out before installation, reducing the time spent on site, and consequently improving project deliverable timelines.

Additionally, it delivers higher retro-reflectivity, improved visibility and uniformity in application whilst its unique dotted line marking system enhances wet night performance by facilitating drainage, ensuring the marking stands proud of surface water, increasing visibility for road users.

The companies say thedeployment of WJ Group’s latest innovations on the high-speed rail scheme, in collaboration with HW Martin (Traffic Management) Ltd, marks a significant step forward in enhancing road worker safety and operational efficiency. By utilising the Autonomous PreMarker and ThermoPrint technologies on the M6/M42 link road, the partnership has shown a potential future for the sector where fewer people are working on the carriageway, whilst also streamlining project timelines.

These innovations demonstrate WJ Group and HW Martin’s commitment to leveraging cutting-edge technology to support the construction of the new high speed rail network, ultimately contributing to a safer and more efficient road network. As the high-speed rail project progresses, the integration of such advanced technologies will continue to play a crucial role in managing the complex demands of this infrastructure project.

(Picture – WJ)