It’s no secret that health and safety has always been a highly relevant talking point within the industry. Construction has consistently been labelled as one of the most dangerous sectors to work in. So far in 2022/23 alone, 135 workers have lost their lives in work-related incidents, an increase of 12 fatalities from the previous two years.

Health and safety management is all about prevention – mitigating risks and rectifying non-conformance before incidents can occur. Having the right processes in place can:

- Reduce costs

- Lower employee absence and turnover rates

- Reduce accidents

- Protect against legal action

- Improve standing with suppliers and stakeholders

- Improve reputation for corporate responsibility among investors, customers and local communities

- Increase productivity by fostering a healthier, happier workforce

There are numerous factors as to why health and safety compliance can sometimes take a backseat. Strict deadlines putting pressure on workers to take shortcuts, management too busy to properly oversee processes, low profitability or simply human error.

Whatever the cause may be, it’s likely exacerbated by inefficient procedures or outdated systems. Companies still utilising paper systems, legacy spreadsheet software or disjointed siloed systems are likely finding themselves lost in a whirlwind of work, with health & safety compliance suffering as a result.

As an ongoing issue, what can be done to prevent incidents and improve processes? Businesses in the industry are increasingly turning to the use of field management software – a digital solution that streamlines communication between sites and the back office, uniting all operational processes under one system.

“How?” Is usually the next question – Here are five applications for field management software that can help businesses master their health and safety processes.

1. Risk Assessments

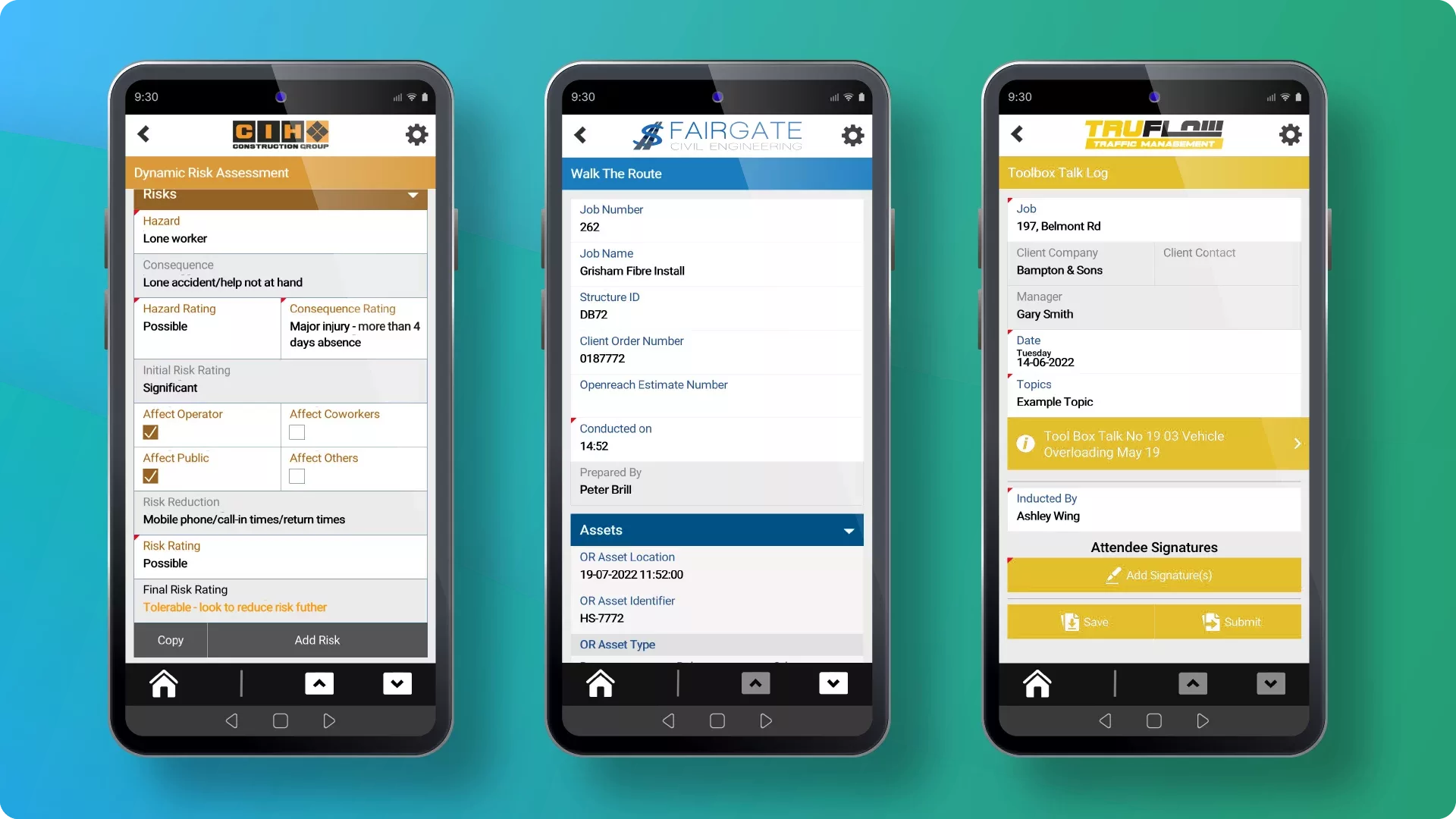

Digital forms such as the dynamic risk assessment ensure a full assessment of potential hazards, utilising intelligent formulas and calculations to automatically identify consequences, probability, who is at risk and what risk reduction is in place, ultimately generating a final risk rating based on the data.

Re-flow, a leading field management solution, offers a catalogue of over 40 pre-built, customisable forms that include standards such as dynamic risk assessment, toolbox talks, vehicle checks and more.

For a job with potentially severe consequences and high incident probability, a dynamic risk assessment can be automated to instantly put works on hold by triggering a notification to management teams that actions need to be taken to mitigate the hazards before work can continue. All this is then be fed back to operatives on site, who can instantly view communicated updates through a mobile app. This empowers workers with the tools to track and feedback on their own safety.

2. Toolbox Talks and Qualifications

Keeping track of operative training and qualifications to ensure everyone on-site remains compliant is essential. With field management software, qualifications, certifications and toolbox talks can be stored and accessed through the app and desktop dashboard. This ensures all operatives are properly qualified and briefed when assigned to a task, with the ability to set up triggers in the scheduler if adequate training is not present.

Toolbox talks are a great way of ensuring all operatives have the relevant information and knowledge to take on the task assigned to them. Scheduling them to take place at the beginning of the workday and making completion mandatory safeguards the workers and keeps the business compliant. Operatives must submit a unique digital signature, with time, date and location attached for further auditability.

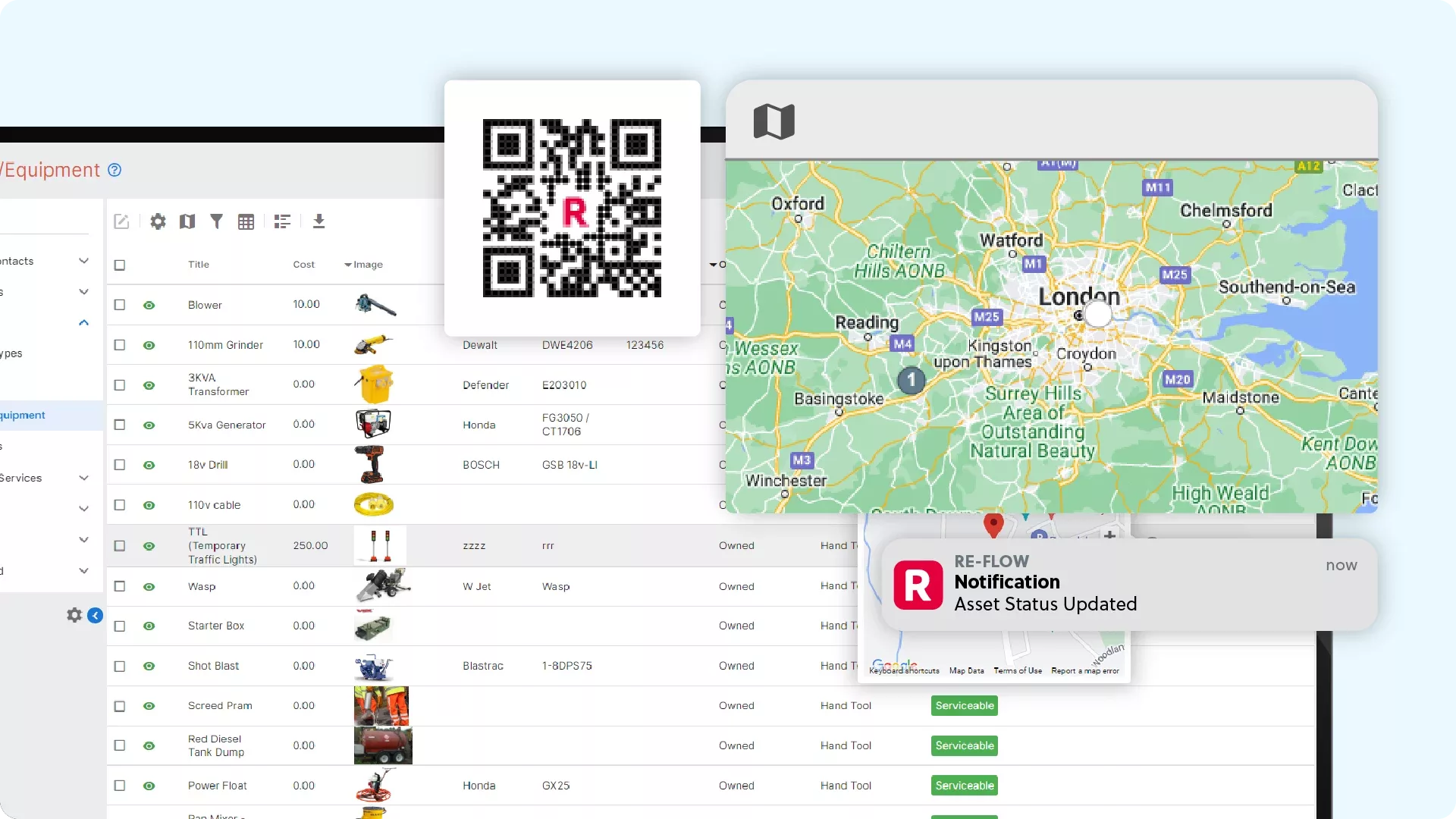

3. Asset Management and PPE

Field management software can help keep track of all your vehicles and assets in one, easily accessible place. With customisable service intervals, detailed safety check records and location tracking, users gain oversight of where equipment is and if it is operational.

Use asset management to gain an instant overview of plant, equipment and vehicles across a wide geographical area, enabling you to track defects, automate service reminders and view locations in real-time.

Automated reminders to complete mandatory vehicle and equipment checks can reduce risks of wear and tear before it becomes expensive and dangerous. There may even be the ability to upload any relevant documents, dos, and don’ts.

Necessary PPE can be accessed through in-app ordering and digital forms, ensuring the proper safety equipment is listed and available. Forms can be built and customised to require photos tagged with time, date and location that prove workers are complying with correct safety standards before further works can proceed.

4. Fatigue Tracking

Forms can also be designed to calculate hours worked. This data can be fed into a fatigue report against each operative working within the organisation. This live data can then trigger alerts around activity, shifts accruing long hours can notify managers, with preventative measures ensuring they cannot be scheduled or carry out works through the app when exceeding their fatigue limits.

5. Instant data and communication

It’s an unfortunate truth, but no matter how robust your preventative measures, accidents can still happen. The only way to reduce incident numbers is to report these near misses and use this information to help improve working practices. This information needs to be stored securely and communicated instantly.

Leading companies in construction, civil engineering, utilities and rail have adopted field management software as part of their field operations, enabling them to facilitate better communication, increased operational efficiency and more.

Through field management software, incidents can be reported instantly through the app, anytime, anywhere. Full records including time, date, location, and parties involved mean that users can gain an instant overview of the situation, take appropriate action, and extrapolate data to build a safer working environment. No more waiting until the forms have been dug out of the van at the end of the month.

Instant communication is also an asset for lone workers. If there is an issue or office staff want to check in with the worker, this can be done instantly through the app. An open line of communication will mitigate risks and ensure no one is left feeling unsafe.

Ultimately, the root of many preventable accidents on-site are inefficient, unreliable HSE processes. This combined with increasing pressure on business owners to meet stricter and stricter deadlines to remain profitable, means corners are being cut to save time and money. Continuing to operate on outdated systems will cost workers their health, livelihoods, and in the most severe cases, lives.

New technologies, like field management software, are being widely adopted by industry leaders and innovators as the way forward to prevent and mitigate risk, ensuring the safety of their current and future workforce.